Commitment to water

JPS Pharmaceutical has been committed to health and quality. Hear from one of our factory managers about one of our commitments, water, which is indispensable for JPS Pharmaceutical’s extract production.

In search of clean water

Water quality fluctuates throughout the year.

JPS Pharmaceutical is particular about the water used for manufacturing, and the answer we have arrived at is purifying water at our own factories.

We always make clean water of constant quality to use for extraction with a water treatment system in our own factories that purify the water with RO membrane filtration.

Everywhere in the factory

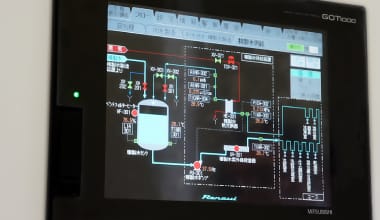

All water for pharmaceutical production in our factories is computer controlled.

Water filtered by the RO membrane is applied to an ion exchange membrane, sterilized by ultraviolet rays, and then circulated in each process, and it can be used as purified water according to the Japanese Pharmacopoeia at any time.

In addition, the water quality (TOC, conductivity) is monitored 24 hours a day.

This quality is the pride of JPS Pharmaceutical.